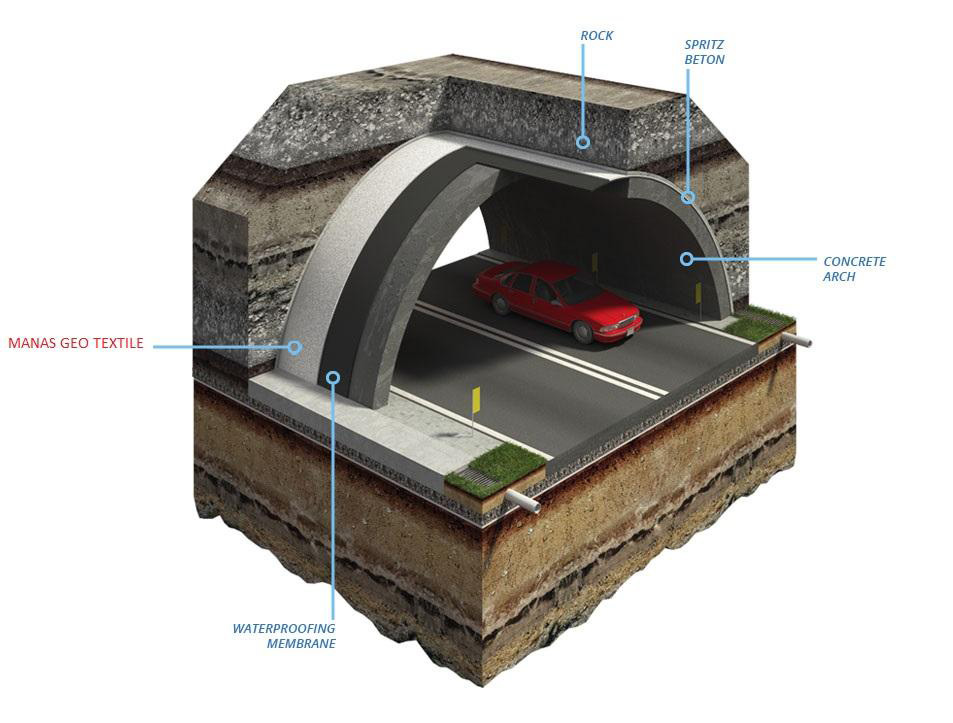

Modern tunnel design and construction involves engineered lining systems that provide effective drainage and a long term moisture barrier for the tunnel walls. After the excavation of the tunnel, the rock is sprayed with concrete (shotcrete) to smooth out the unevenness of the rock face. Either a geocompsite or needle- punched Non-Woven geotextile i s then placed on the sprayed concrete and anchored using steel bolts coupled with polymer fastening discs. The Tunnel liner (HDPE membrane) is then welded to the discs. After the weld testing a final concrete layer (ring concrete) is put in place.

1. Protection of the linear from abrasion and puncture by protrusions from the base surface of the tunnel well.

2. Drainage of water seeping through the rock and sprayed concrete layer. The in-plane oermeability of the geotextile enables the water to flow to a subsurface drainage collection system. Where it is directed away from the tunnel

and Bangalore . Our main advantage is that we have an carded automated needle punched fibre machine imported from Germany which provides us an edge in terms of quality, needle precision , size texture and strength.

Mr Kanodia is the founder and chairman of the Kanodia group. From Kanodia Builders