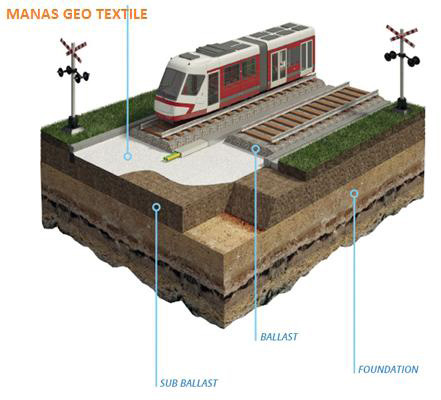

Our Products provides inherently stronger track system that lasts longer, requires little maintenance, and produces a net cost savings. For new track or repairs, there's no need to remove native soil. Install Our Products directly on the sub grade and eliminate contamination from below the ballast.

Our Products bonds tightly between ballast and subsoil, preventing fine soils from pumping upwards and contaminating the ballast. Its coarse texture also prevents train action from pumping soils laterally, causing the track surface to drop.

Our Products installed between ballast and sub grade effectively reinforces the rail bed. Drains water quickly so that ballast remains dry and functional. In Railroad applications, toughness and permeability are critical factors due to the dynamic loads imposed by 100 tonne and 200 tonne locomotives. Our Products has necessary tensile and elongation properties to spread these track loads over a large area thus reducing the unit pressure on the soil. This not only increases the load carry capacity of railbed, but it also evens out the dynamic loads and lessens the tendency of the track to become centreboard -- a condition in which the soil at the centre of the track loses its stability.

and Bangalore . Our main advantage is that we have an carded automated needle punched fibre machine imported from Germany which provides us an edge in terms of quality, needle precision , size texture and strength.

Mr Kanodia is the founder and chairman of the Kanodia group. From Kanodia Builders