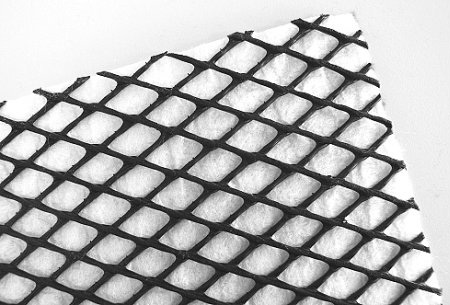

At Manas, we offer a wide range of GeoTextile fabrics that are designed to perform distinctive functions, such as separation, filtration, drainage, cushion, and reinforcement. These pre-engineered solutions are cost-effective as well as time-saving for different applications, including ground stabilization, coastline and riverbed protection, landfill engineering, drainage and others.

We manufacture Geo Textiles at our manufacturing facility in Haryana where we have European fully-automated needle punching machines for manufacturing products with world-class standards. We use polypropylene/ polyester staple fiber for manufacturing Non-WovenGeo Textiles with a precise needle punching that lead to the formation of a strong and flexible structure with high permeability. We have a large production capacity and we can deliver our products to your project sites in a timely manner. The products are tested in our in-house laboratory before delivery.

We also supply nonwoven geo-textiles of smaller widths to be used for pasting at project sites. These are cut uniformly by automated machines and can easily be pasted at sites, without a need of cutting them manually. While it saves time and labor, it also helps maintain the surface smoothness, which otherwise may not be possible by manual cutting.

We also manufacture nonwoven geo-textile of custom widths that are suitable for wrapping on PVC pipes. The geo-textile wrapping acts as a shock cover layer for perforated PVC pipes. The textile fabric is largely used in subsurface drainage projects in India to prevent sand and gravel from entering the PVC pipe and blocking it. The geo-textile fabrics are available in custom widths of 0.1 Meter to 5 Meter for wrapping perforated PVC pipes.

Manas manufactures high strength Non-Woven Geo Bags for Coastal Protection. These bags can be filled with sand and are used for riverbed, beach and coastline protection. These bags form a low-cost, reversible solution for the protection of hydraulic structures by reinforcing the existing barriers of the river banks, beach fronts and other water bodies. In comparison to conventional practices oF using gravels and hard rocks for erosion protection, sand-filled Geo Bags are an effective, low-cost alternative. Bags can be filled with locally available sand, instead of transporting boulders which can incur high costs.

We have an in-house capacity of producing various types of Geo Bags, including 300 GSM Geo Bag and 400 GSM Geo Bag, made out of polyester and polypropylene Geo Textile. We can also customize the bags sizes to suit the design and installation requirements of a project. Our Geo Bag manufacturing unit boasts of the latest machines to help us achieve the best quality and a very high production output.

With the conventional well graded filter, there are chances for the clogging of filter in longer duration and will affect the drainage functioning severely. Especially for reinforced soil wall applications, our utmost need is to avoid increase in pore water pressures.

Geo Composite is designed with inner core for drainage and outer jacket of Non-Woven Geo Textile for filtration.

Manas Drainage composite is a cost effective alternate solution to the conventional system and now a days there is a scarcity of conventional filter material in most of the areas so it is indeed a step towards saving of our national assets too.

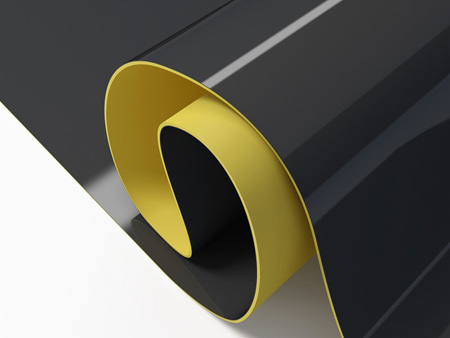

We have set up a new PVC Geo Membrane plant after working in the tunnel industry for closely 6 years. Our PVC sheet membranes are manufactured using superior raw materials chosen for strength and durability, providing PVC waterproofing membranes a long sustainable life. The Manas Membrane has an elongation of over 300% allowing a structure to move without tearing/splitting the membrane while maintaining the waterproofing integrity.

PVC Membrane has been found to form part in many Tunnels Waterproofing Specifications while also being the most preferred Membrane to Waterproof Tunnels as PVC Membranes are:

Manas PVC (Polyvinyl Chloride) Geo Membrane is a single-layer membrane consisting of two different colours of layers. It is light coloured on one side & black on the other. The light colour helps in identifying the damages that may occur during application. PVC membranes have a wide range of benefits for tunnels, the most important is cost-saving in remediation, repairs, maintenance, or replacement over the expected lifespan of the project.